Mayfran – Your partner for Coolant and Filtration Systems worldwide!

Consolidated with their holding company "Tsubakimoto", Mayfran is exhibiting, with its sister company KabelSchlepp, a wide range of products for metal cutting applications on its 240 m² stand.

Mayfran International has been actively working for over 75 years in the machine tool industry. All 3 production sites in Cleveland USA, Shiga in Japan and Landgraaf in the Netherlands act as hubs for a globally effective service network. The listed holding company “Tsubakimoto Chain” from Osaka, Japan, is the world market leader in drive and roller chains as well as supplier of large conveyor chains for a diverse range of applications in various industrial sectors. The Tsubaki Group comprises 46 production sites and 63 subsidiaries worldwide. At EMO 2019 Mayfran International is focusing on the fields of chip management and coolant filtration. Mayfran is the original equipment manufacturer for filter and chip conveyor systems for some of the largest machine tool manufacturers in the world. Customer expectations and demands on machine tools are increasing continuously, so the peripherals supplied by Mayfran are also developing to match.

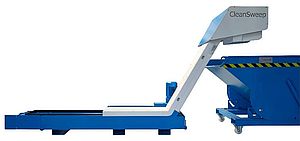

Cleansweep – the next Generation of Conveyors!

Mayfran’s chip conveyor “Cleansweep RM” closes the gap between belt conveyors and the filter systems such as the ConSep model. In the Cleansweep the hinged conveyor belt in augmented with a screen box, which is located between the upper and lower strands of the conveyor belt. The filter screen is continuously cleaned by a series of scrapers or carriers. The patented inner chip handling system ensures efficient discharge of the chips. The Cleansweep technology is particularly effective for applications producing fine and short chips. The self-cleaning screen box intercepts the particles that have washed through the hinged belt and these are then transferred to the discharge point.

Mayfran’s chip conveyor “Cleansweep RM” closes the gap between belt conveyors and the filter systems such as the ConSep model. In the Cleansweep the hinged conveyor belt in augmented with a screen box, which is located between the upper and lower strands of the conveyor belt. The filter screen is continuously cleaned by a series of scrapers or carriers. The patented inner chip handling system ensures efficient discharge of the chips. The Cleansweep technology is particularly effective for applications producing fine and short chips. The self-cleaning screen box intercepts the particles that have washed through the hinged belt and these are then transferred to the discharge point.

Modular Filter Systems – Select the optimal modules for every application!

Also shown are 2 filter modules from the MMF program. In this modular system 3 different filter types are available in several different sizes, giving many possibilities for the user. The filter modules, tank types and sizes can be selected depending on the swarf type, degree of filtration, particle size and space available. The MMF program offers solutions for individual or small groups of machine tools. But Mayfran also supplies tailor made central coolant filtration systems with flow rates up to 25,000 L / min for many well-known manufacturing companies worldwide

Also shown are 2 filter modules from the MMF program. In this modular system 3 different filter types are available in several different sizes, giving many possibilities for the user. The filter modules, tank types and sizes can be selected depending on the swarf type, degree of filtration, particle size and space available. The MMF program offers solutions for individual or small groups of machine tools. But Mayfran also supplies tailor made central coolant filtration systems with flow rates up to 25,000 L / min for many well-known manufacturing companies worldwide

Chip Processing – compact and efficient!

At our booth we are presenting a compact chip processing plant. It consists of a chip shredder of our MA 4.1 product series and a chip centrifuge from the VBU series. This plant is designed to process swarf from multiple machine tools reducing the volume and recovering coolant from wet chips. This model also has an automatic tramp part separation system, which ensures high availability for the entire system.

At our booth we are presenting a compact chip processing plant. It consists of a chip shredder of our MA 4.1 product series and a chip centrifuge from the VBU series. This plant is designed to process swarf from multiple machine tools reducing the volume and recovering coolant from wet chips. This model also has an automatic tramp part separation system, which ensures high availability for the entire system.

ASB - Automatic System for separating particles in the clean tank!

The new product ASB is a magnetic separator, which is embedded in the clean tank. The ASB (Automatic Sludge Barrier) is a compact and portable magnetic separation system that continuously removes small ferrous particles to prevent sludge from accumulating in the coolant tank. The device simplifies the recovery of ferromagnetic contaminants, is easy to service and is ideal for steel and / or cast iron applications. Retrofitting is possible in most coolant tanks.

The new product ASB is a magnetic separator, which is embedded in the clean tank. The ASB (Automatic Sludge Barrier) is a compact and portable magnetic separation system that continuously removes small ferrous particles to prevent sludge from accumulating in the coolant tank. The device simplifies the recovery of ferromagnetic contaminants, is easy to service and is ideal for steel and / or cast iron applications. Retrofitting is possible in most coolant tanks.