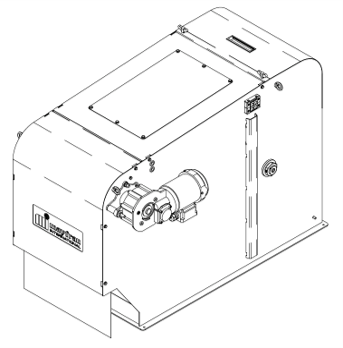

DPF Deepbed Paper Filter

DPF - the compact paper filter unit

As a deep-bed paper band filter from the MMF series, the DPF impresses with its compact design and a good price-performance ratio.

Its optimized design uses hydrostatic pressure to achieve efficient filtration of the cooling lubricant.

High filter fineness combined with low paper consumption make the DPF an intelligent solution for modern demands on cooling lubricant preparation.

- Good value for money

- Super compact design (40% less floor space, compared to most other paper filters with similar flow capacity)

- Suitable for all machining processes

- High filter fineness

- 100% side seal efficiency by special Tsubaki chains

mode of operation

Contaminated cutting fluid enters the filter unit from the side into the inlet diverter.

In the filter housing, the coolant flows through the paper media into the clean tank, while swarf and other residues stay on the paper media.

Swarf and other residues build up and form a filter cake on the paper media and cause the fluid level in the filter to rise until a level sensor is actuated.

The scraper conveyor then removes contaminated paper, swarf and other residues into a collecting container

| Model | Outer Frame Dimensions | Max Flow Rate | |||

|---|---|---|---|---|---|

| Width | Length | Height | Emulsion 1cSt | Oil 15cSt | |

| [mm] | [mm] | [mm] | [l/min] | [l/min] | |

| DPF300 | 773 | 1052 | 882 | 300 | 180 |

| DPF400 | 838 | 1422 | 882 | 400 | 240 |

| DPF500 | 1038 | 1422 | 822 | 500 | 300 |

| DPF700 | 1338 | 1299 | 822 | 700 | 420 |

- Video / Animation

- Brochure

- Contact